A forklift is a truck that is used to move heavy objects by lifting them with a fork-like device. Forklifts are commonly used in warehouses and other industrial settings. They can also be used for moving furniture and other large objects. Most forklifts have a capacity of around 3,000 pounds. They can be used to move objects in any direction, including sideways and up and downstairs. Forklifts are powered by either gasoline or diesel engines. At CPN Training, we provide forklift training in Brixham and surrounding areas.

Forklifts come in a variety of sizes and types. There are three main types of forklifts: standard, reach and counterbalance. Standard forklifts are the most common type and have a straight arm that is used to lift the object. Reach forklifts have an arm that bends at the elbow, which allows them to lift objects that are further away. Counterbalance forklifts are used to lift very heavy objects. They have a large counterweight on the back of the forklift that makes it easier to lift heavy objects.

The history of the forklift

Forklifts have been around for over one hundred years, since the late 1800s. They were initially designed to carry loads of coal or steel. The first forklifts were powered by steam engines. In the early 1900s, gasoline and diesel engines began to be used in forklifts

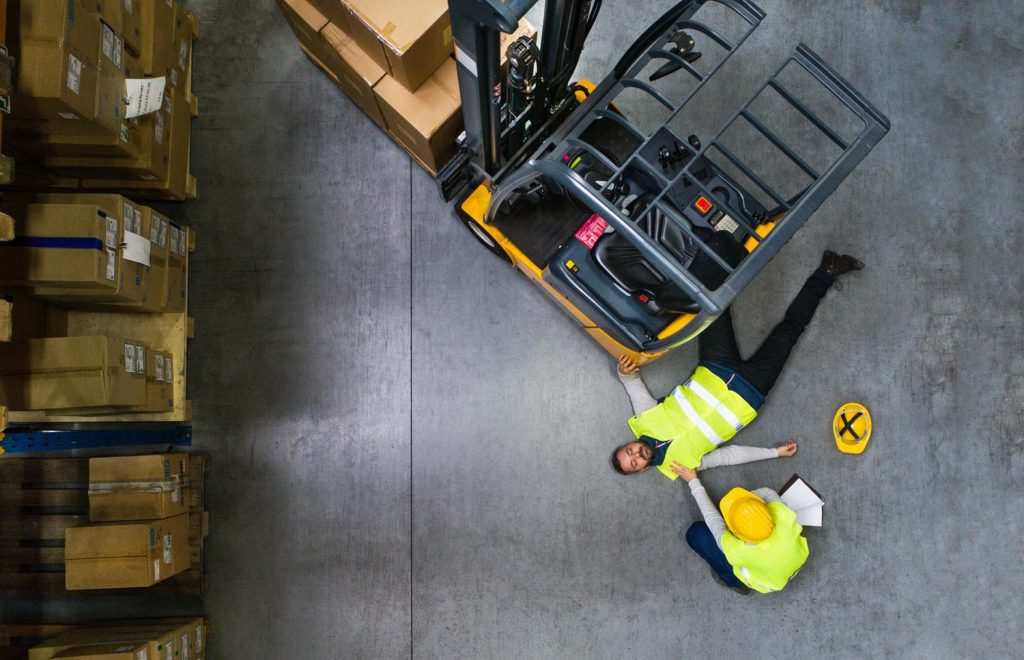

Forklift safety

Forklift safety is a top priority for warehouses and other industrial facilities. Forklifts can be dangerous if they are not operated correctly. There are a number of safety features that are included on all forklifts, such as,

– Seat belts

– Horn

– Reverse alarm

– Brakes

– Mirrors

Operators must be trained on how to use forklifts safely before they are allowed to operate them. It is important to always follow the operator’s manual when using a forklift. Improper use of a forklift can result in serious injury.

Forklift accidents

Despite the safety features that are included on forklifts, accidents do happen. Most forklift accidents occur when the operator is not following the safety guidelines. Some common causes of forklift accidents include,

– Improper use of the forks

– Operating the forklift at too high a speed

– Driving under a raised load

– Falling off the forklift

– Accidental activation of the reversing alarm

– Getting caught in between objects being moved by the forklift

The best way to avoid forklift accidents is to always follow the safety guidelines and be aware of your surroundings. Operators should never operate a forklift if they are feeling tired or distracted.

Conclusion

The forklift is a truck that can be used to move heavy objects by lifting them with its forks. The first-ever forklifts were powered by steam engines, while today they are typically powered either by gasoline or diesel engines and come in three main types: standard, reach and counterbalance. All of these different factors make the use of a forklift an important consideration for warehouses and other industrial settings. Operators must also follow safety guidelines when using the machines so as to avoid accidents such as falling off the forklift or getting caught between two moving objects. Get in touch with us today for forklift training in Brixham and surrounding areas.